UMbhobho we-STEEL WE-CARBON IKHABHNINI ONGENAMTHUNGO WESTEEL.

Inkcazo

Umbhobho wentsimbi ongenamthungo wenziwa ngentsimbi engqukuva eyomeleleyo 'billet' ethi ifudunyezwe ize ityhale okanye itsalwe phezu kohlobo oluthile de intsimbi ibunjwe ibe yityhubhu enomgongxo.Umbhobho ongenamthungo ke ugqityezelwe kwimilinganiselo yobukhulu kunye nobukhulu bodonga ngokobukhulu ukusuka kwi-1/8 intshi ukuya kwi-intshi ye-OD engama-32.ICarbon Steel Seamless Pipes / Iityhubhu Ikhabhoni yentsimbi yingxubevange ebandakanya intsimbi kunye nekhabhoni.Ipesenti yekhabhoni kwintsimbi ichaphazela ubunzima, amandla e-elasticity kunye ne-ductility ye-carbon steel.Umbhobho wentsimbi ye-carbon engenamthungo okanye i-ingot yensimbi eqinileyo yenziwe ngetyhubhu ye-capillary ngokusebenzisa umngxuma, emva koko nge-hot-rolled, cold rolled or cold call yenziwa.Umbhobho wentsimbi yekhabhoni engenamthungo kwishishini lentsimbi yaseTshayina unendawo ebalulekileyo.Izinto zemibhobho yentsimbi yekhabhoni engenamthungo yityhubhu engqukuva, iimbumba zomatshini wokusika umbhobho ukuze zihambe ngokusika malunga ne-1 m ubude obungenanto, kwaye zithunyelwe ngokufudumeza isithando somlilo.I-Billet yondliwa kwisithando somlilo, iqondo lokushisa li malunga ne-1200 degrees Celsius.Amafutha yihydrogen okanye iacetylene.Ulawulo lobushushu bomlilo ngumba ophambili.Ityhubhu engqukuva yaphuma ukuze igqobhoze kumatshini ngoxinzelelo lomoya.Ngokuqhelekileyo i-punch eqhelekileyo ngumatshini wokugqobhoza, i-punch ephezulu yemveliso, umgangatho wemveliso, ukwandiswa komngxuma omkhulu, unokunxiba iindidi zentsimbi.I-Perforation, ityhubhu ejikelezayo ibe kwi-three-roll cross rolling, i-rolling okanye i-extrusion.Icudiswe kumbhobho emva kokulinganisa.Ubukhulu ngesantya esiphezulu se-rotary cone gqobhoza imingxuma kwibillet ukwenza ityhubhu.Idayamitha yombhobho ngokulinganisa ilitye ukumisela ubude bombhobho wedayamitha.Emva kombhobho ngokulinganisa kwinqaba yokupholisa, ukupholisa ngokutshiza ngamanzi, intsimbi emva kokupholisa, kufuneka iqondiswe.Emva kwebhanti yensimbi ethunyelwe ngomatshini wokuvavanya isinyithi (okanye uvavanyo loxinzelelo) kuvavanyo lwangaphakathi.Ukuba umbhobho wangaphakathi uqhekeka, amaqamza kunye nezinye iingxaki ziya kubonwa.Emva kombhobho kodwa kwakhona ngokusebenzisa ulawulo olungqongqo lomgangatho ukhetho manual.Umgangatho wentsimbi, ukusetyenziswa kwamanani epeyinti yokutshiza, iinkcukacha, inombolo yemveliso yemveliso.Ngekhreyini engena kwindlu yokugcina impahla.

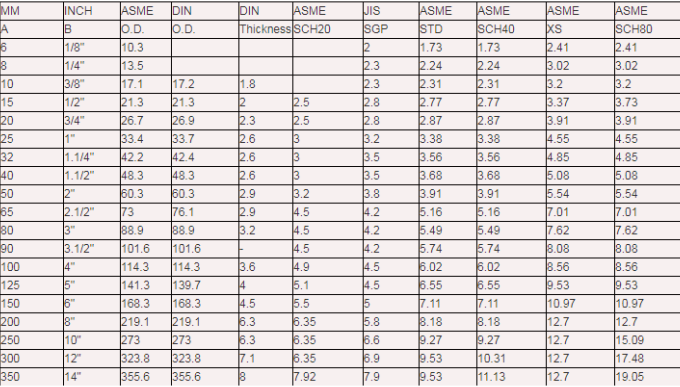

Ubukhulu bodonga lombhobho ongenamthungo

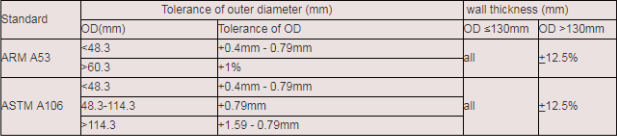

Ukunyamezelwa kweDayimitha yaNgaphandle kunye nobunzima boDonga

Inkcazo

| Umgangatho | Inkcazo |

| I-ASTM A179/A179M | Umthungo ongenamthungo otsalwa yintsimbi ephantsi ingxubevange yobushushu kunye neetyhubhu zecondenser. |

| API 5L | Umbhobho womgca. |

| I-ASTM A53M | Umnyama kunye neZinc eQotywe ngokuWelded kunye noMbhobho wentsimbi ongenamthungo. |

| I-ASTM A106M | Umbhobho wentsimbi yekhabhoni engenamthungo kwinkonzo yobushushu obuphezulu. |

| I-ASTM A105M | Iintsimbi zekhabhoni ezifakela izicelo zemibhobho. |

| I-ASTM A234M | Ukufakwa kwemibhobho yentsimbi yekhabhoni kunye nentsimbi ye-alloy yenkonzo ephakathi kunye nobushushu obuphezulu. |

Umgangatho

| Umgangatho | Uhlobo lombhobho | Iklasi | IBanga |

| API SPEC 5L ISO 3183 | I-SMLS | PLS1 | L245B, L290 X42, L320 X46 , L360 X52, L390 X56, L415 X60, L450 X65, L485 X70 |

| PLS2 | L245N BN, L290N X42N, L320N X46N, L360N X52N, L390N X56N, L415N X60N, L360Q X52Q, L390Q X56Q, L415Q X60Q , L485Q X70Q | ||

| PLS2 Ubume obumuncu | L245NS BNS, L290NS X42NS, L320NS X46NS L360NS X52NS, L390NS X56NS, L415NS X60NS, L360QS X52QS, L390QS X56QS, L415QS X60QS L485QS X70QS | ||

| WELD | PLS1 | L245B, L290 X42, L320 X46, L360 X52 L390 X56, L415 X60, L450 X65, L485 X70 | |

| PLS2 | L245M BM, L290M X42M, L320M X46M, L360M X52M, L390M X56M, L415M X60M, L450M X65M, L485M X70M, L555M X80M, |

| Umgangatho | IBanga |

| I-ASTM A 53 M | A, B |

| I-ASTM A 106M | A, B, C |

| JIS G 3454 | STPG 370, STPG 410 |

| JIS G 3455 | STPG370, STPG410, STPG480 |

| JIS G 3456 | STPG370, STPG410, STPG480 |

Ibakala: Ukwakheka kwemichiza (%):

| Umgangatho | IBanga | C | Si | Mn | P | S | Ni | Cr | Cu | Mo | V |

| I-ASTMA 53M | A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | - | ≤1.20 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| I-ASTM A 106M | A | ≤0.25 | ≥0.10 | 0.27-0.93 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| JIS G 3454 | STPG 370 | ≤0.25 | ≤0.35 | 0.30-0.90 | ≤0.040 | ≤0.040 | - | - | - | - | - |

| STPG 410 | ≤0.30 | ≤0.35 | 0.30-1.00 | ≤0.040 | ≤0.040 | - | - | - | - | - | |

| JIS G 3455 | I-STS 370 | ≤0.25 | 0.10-0.35 | 0.30-1.10 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| I-STS 410 | ≤0.30 | 0.10-0.35 | 0.30-1.40 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| I-STS 480 | ≤0.33 | 0.10-0.35 | 0.30-1.50 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| JIS G 3456 | STPT 370 | ≤0.25 | 0.10-0.35 | 0.30-0.90 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| STPT 410 | ≤0.30 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| STPT 480 | ≤0.33 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - |

Ukupeyinta&Ukwaleka

Unyango lomphezulu wombhobho wentsimbi: Ukuze kuphuculwe ubomi benkonzo yombhobho we-oyile, unyango lomphezulu ludla ngokuqhutywa ukuququzelela indibaniselwano eqinileyo yombhobho wentsimbi kunye ne-anticorrosive coating. iindidi ezine.

1. Ukucoca Igrisi, uthuli, i-lubricant, i-organic matter ehambelana nomphezulu wepayipi yensimbi, ngokuqhelekileyo isebenzisa i-solvent, i-emulsion yokucoca indawo. ngoko ke ezinye iindlela zonyango ziyafuneka.Isixhobo sokususa umhlwa Umbhobho wentsimbi umphezulu we-oxide, umhlwa, i-welding slag, unokusebenzisa ibrashi yocingo yentsimbi ukucoca kunye nokugulisa unyango lomphezulu.

I-2.Tool derusting inokwahlulwa ibe yi-manual kunye namandla, i-manual tool derusting inokufikelela kwinqanaba le-Sa 2, isixhobo samandla derusting sinokufikelela kwinqanaba le-Sa3.Ukuba ubuso bombhobho wensimbi udityaniswe nesikhumba se-oxide esomeleleyo, kunokuba nzima ukususa. umhlwa ngoncedo lwezixhobo, ngoko kufuneka sifumane ezinye iindlela.

I-3.I-Pickling Iindlela eziqhelekileyo zokukhetha ziquka i-chemistry kunye ne-electrolysis.Kodwa kuphela i-chemical pickling isetyenziselwa ukukhuselwa kwe-pipeline corrosion.I-Pickling ye-Chemical pickling inokufezekisa iqondo elithile lokucoceka kunye noburhabaxa phezu kombhobho wensimbi, olungele imigca ye-anchor elandelayo. Ngokuqhelekileyo njengoko imbumbulu (isanti) emva kokulungiswa kwakhona.

4.Ukudubula ukudubula ukususwa kwe-rust.Ngokuqhuba i-motor yamandla aphezulu, ii-blades ezijikelezayo zesantya esiphezulu, i-grit yensimbi, i-steel shot, i-segment, iiminerali kunye nolunye ucingo lwe-abrasive phantsi kwesenzo samandla e-centrifugal kwi-spray yentsimbi yombhobho wokutshiza kunye nokukhupha ubunzima, susa ngokucokisekileyo. umhlwa, i-oxides kunye nokungcola kwelinye icala, kwelinye icala, umbhobho wentsimbi phantsi kwesenzo sempembelelo yobundlobongela oburhangqileyo kunye namandla okukhuhlana, ukuphumeza uburhabaxa obufunekayo. ukucima umbhobho.Ngokubanzi, ukudutyulwa kokudubula kunye nokuchithwa kusetyenziswa ikakhulu kunyango lwangaphakathi lombhobho wentsimbi, kwaye ukudutyulwa nokudutyulwa kusetyenziswa ikakhulu kunyango lwangaphandle lombhobho wentsimbi.

Ukupakisha&Ilayisha

Ipeyinti yokutshiza

Ukupakishwa kwamanzi