I-BOILER ENGENAMTHUNGO ityhubhu yesibhobhobhobhobhobhobhoyi BOILER

Inkcazo

Iityhubhu zebhoyila yenye yepayipi engenamthungo.Iindlela zokuvelisa ziyafana netyhubhu engenamthungo, kodwa ineemfuno ezingqongqo zokwenza imibhobho yentsimbi.Ngokwenqanaba lobushushu, ityhubhu yebhoyila yahlulwe ibe yityhubhu yebhoyila ngokubanzi kunye netyhubhu yebhoyila yoxinzelelo oluphezulu.

Iindlela zokuvelisa:

① Ubushushu betyhubhu yebhoyila ngokubanzi bungaphantsi kwama-450 ℃, kusetyenziswa umbhobho oqengqelekayo oshushu okanye umbhobho otsalwa ngokubanda wenza umbhobho wentsimbi.

② ityhubhu yebhoyila yoxinzelelo oluphezulu isetyenziswa rhoqo kwiimeko zobushushu obuphezulu kunye nombhobho woxinzelelo oluphezulu, ifuthe lobushushu obuphezulu begesi kunye nomphunga wamanzi, i-oxidation kunye nokuhlwa.Umbhobho wensimbi onamandla amakhulu okuqhekeka, ukuchasana okuphezulu kwi-oxygen corrosion kwaye ube nokuzinza okuhle kwentlangano.

Iinjongo zebhobho yebhoyila:

① Iityhubhu zebhoyila ngokubanzi zisetyenziselwa ukwenza iityhubhu eludongeni lwamanzi, iityhubhu emanzini abilayo kunye nombhobho oshushu kakhulu, iityhubhu zebhoyila ezishushu kakhulu, umbhobho omkhulu kunye omncinci kunye nezitena zearch.

② ityhubhu yebhoyila enoxinzelelo oluphezulu isetyenziswa ikakhulu ukwenza uxinzelelo oluphezulu kunye neetyhubhu zoxinzelelo oluphezulu lwebhoyila, iityhubhu zokufudumeza kwakhona, indlela yomoya, owona mbhobho womphunga.

Udidi:

Iityhubhu zebhoyila ngokubanzi kunye netyhubhu yebhoyila yoxinzelelo oluphezulu ibonakaliswa ekusebenzeni kobushushu obuphezulu.Iityhubhu ze-boiler ngokubanzi, okanye iityhubhu zebhoyila zoxinzelelo oluphezulu ngokwendlela yokusetyenziswa kwazo zinokuhlulwa zibe ziindidi zemibhobho yentsimbi.

Inkcazo

Imigangatho kunye nezinto eziphathekayo zombhobho wensimbi zifumaneka kwikhabhoni, i-alloy, kunye ne-stainless steel material.

Intsimbi yekhabhoni:ASTM/ASME A/SA 106, ASTM A179, ASTM A192, ASTM/ASME A/SA 210, ASTM A333 Gr 1, 6,7 ukuya kwiGr 9,

Intsimbi yealloyi:I-ASTM/ASME A/SA 213 T1, T2, T5, T9, T11, T12, T22, T91, T92;I-ASTM A335 P1, P2, P5, P9, P11, P12, P22, P91, P92

Yenziwe ngentsimbi eshayinayo:I-ASTM A268, i-ASTM A213, TP304/L, TP316/L, 310S, 309S, 317,317L, 321,321H, kunye ne-duplex yensimbi engenasici njl.

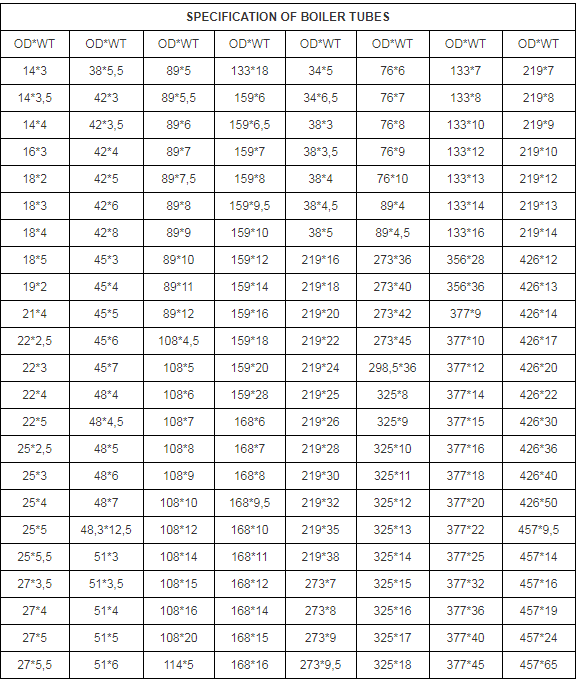

Ubungakanani obuqhelekileyo: OD ukusuka 6mm ukuya 1240mm, ubukhulu ukusuka 1mm ukuya 50mm

Iintlobo:Umbhobho webhoyila othe tye, kunye nombhobho wentsimbi webhoyila we-U kwibhoyila yokutshintshiselana ityhubhu.

Le migangatho ichaza ukuhlelwa, ubungakanani, imilo, ubunzima kunye nokuphambuka okuvumelekileyo, iimfuno zobugcisa, ukuhlolwa kunye nokuvavanya, ukupakishwa, ukuphawula kunye nesiqinisekiso somgangatho weetyhubhu zetsimbi ezingenamthungo kwibhoyili.

Imigangatho

I-GB(imigangatho yeSizwe yamaTshayina)

(1) I-GB 3087: Iityhubhu zentsimbi ezingenamthungo kwibhoyila ephantsi kunye nephakathi

(2) GB 5310: ityhubhu yentsimbi engenamthungo kwibhoyila yoxinzelelo oluphezulu

(3) I-GB 13296: Iityhubhu zentsimbi ezingenamthungo kwiibhoyila kunye nabatshintshisi bobushushu

(4) I-GB 6479: Iityhubhu zentsimbi ezingenamthungo zezixhobo zesichumiso zekhemikhali ezinoxinzelelo oluphezulu

(5) I-GB 9948: Iityhubhu zentsimbi ezingenamthungo zokuqhekeka kwepetroleum

I-ASME(Uluntu lwaseMelika lweenjineli zoomatshini)

1

(2)ASME SA-192M: Iityhubhu zeBoiler zentsimbi zeCarbon ezingenamthungo zoxinzelelo oluphezulu

(3)ASME SA-209M: Umthungo wecarbon-Molybdenum Alloy-Steel Boiler kunye neSuper heater Tubes

4

5

(6)ASME SA178: IBoiler yeNtsimbi yeCarbon-Manganese eDityanisiweyo yoMbane kunye nesifudumezisi esikhulu

I-ASTM(imigangatho yeSizwe yamaTshayina)

(1) I-ASTM A213: Ibhoyila yensimbi engenamthungo ye-ferritic kunye ne-austenitic alloy steel, iheater enkulu kunye neityhubhu zokutshintsha ubushushu

(2)SA213-T2: I-ASME SA213 T2 inoxinzelelo oluvumelekileyo oludweliswe ukuya kuthi ga kwi-1000F kwiKhowudi yeBhola ye-ASME.

(3)SA213-T9

(4) SA213-T12: I-Ferritic engenamthungo kunye ne-Austenitic Alloy-Steel Boiler, i-Superheater, i-Heat-Exchanger Tubes.

5

(6) I-SA213-T22: I-ASM T22 Boiler Tube yityhubhu ephezulu yokunyamezela ukushisa esetyenziselwa kwiindawo ezinobumuncu kunye ne-corrosive ezifana ne-hydrochloric processing kunye ne-aluminium chloride catalyst ebandakanya izicelo.

(7)ASTM A 106M: Umbhobho weNtsimbi weCarbon ongenamthungo kwiNkonzo yoBubushushu obuphezulu

(8) I-ASTM A192M: Iityhubhu zeBoiler zeNsimbi zeCarbon ezingenamthungo zoxinzelelo oluphezulu

(9)ASTM A210M: Ibhoyila yentsimbi yekhabhoni engasemthungo ePhakathi kunye neeTubhu zeHeatheater

(10)ASTM A 335M: Umbhobho wentsimbi ye-ferritic engenamthungo yenkonzo yobushushu obuphezulu

EN(Deutsche industrie normen)

I-EN 10216-2: Iityhubhu zentsimbi ezingenamthungo ngeenjongo zoxinzelelo

I-DIN

I-DIN 17175:Iiityhubhu ezingenamthungo zeentsimbi ezinganyangekiyo kubushushu-Iimeko zobuGcisa zokuHanjiswa

I-JIS

(1) I-JIS G3461: Ibhoyila yensimbi yeCarbon kunye neetyhubhu zokutshintsha ubushushu

(2) I-JIS G3462: Ibhoyila yensimbi ye-alloy kunye neetyhubhu zokutshintsha ubushushu

(3) I-JIS G3463: I-Stainless Steel ye-Boiler kunye ne-Heat Exchanger Tubes

IZIYINQI EZINGAGQI

I-SA213-T304:- I-SA 213 Tp 304 Material iqukethe i-18% ye-chromium kunye nekhabhoni, i-manganese, i-phosphorus, isulfure, i-silicon kunye ne-nickel ekubunjweni.

I-SA213-T316:– I-SA213 TP316 Iityhubhu ngumgangatho wezinto eziphathekayo kwiityhubhu zokutshintsha ubushushu ezenziwe kwi-316 austenitic steel stainless.

I-SA213-TP321 & 347– I-SA213 TP321 luphawu lweityhubhu zokutshintsha ubushushu ezenziwe kwi-321 austenitic stainless steel.

Ukupeyinta&Ukwaleka

Baze, Ioyile kaKhala, Mnyama/Bomvu/Mthubi, Ukupeyinta, Zinc/Anti-ukugquma.

Ukupakisha&Ilayisha

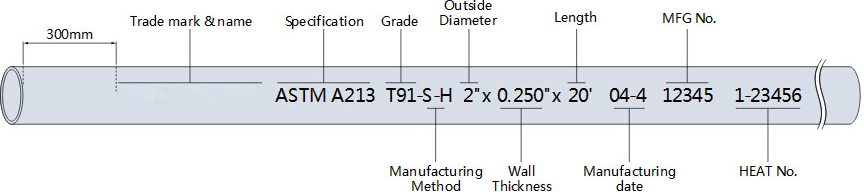

Ukumakishwa okusemgangathweni