I-ALLOY ENGENAMTHUNGO UMbhobho we-ALLOY TUBE IXESHA ELIPHEZULU UMbhobho WEntsimbi

Inkcazo

OD: 6-720MM

WT: 0.5-120MM

Ubude: 3-16M

Isicelo:IPetroleum, ubuNjineli beMichiza, uMbane, iBoiler

Umgangatho: ASTM A335/A335M, ASTM A213/213M, DIN17175-79, JIS3467-88,GB5310-95

Izinto:P5,T5,P11,P12,STFA22,P22,T91,T9,WB36

Umbhobho we-alloy luhlobo lombhobho wensimbi ongenamthungo, ukusebenza kwawo kuphezulu kakhulu kunombhobho wentsimbi ongenamthungo, kuba olu hlobo lombhobho wentsimbi luqulethe i-Cr, ukumelana nobushushu obuphezulu, ukumelana nobushushu obuphantsi, ukusebenza kokumelana nomhlwa kubhetele kakhulu kunezinye. Umbhobho wensimbi , ngoko umbhobho we-alloy usetyenziswa ngokubanzikwi-petroleum, i-aerospace, ikhemikhali, amandla ombane, ibhoyila, umkhosi kunye namanye amashishini.

ityhubhu ye-alloy ibhekisa kusetyenziso lwe-alloy extrusion process ibe yintsimbi ye-tubular material, enokuthi ivalwe enye okanye ngaphezulu ngemingxunya, ubukhulu bodonga kunye necandelo lomnqamlezo ofanayo, elisetyenziswa kwiimoto, iinqanawa, i-aerospace, i-aviation, umbane, ezolimo, i-electro mechanical, ikhaya kunye namanye amashishini.

Inkcazo

Ukuqulunqwa kwemichiza

| C, % | Mnu, % | P, % | S, % | Si, % | Cr, % | Mo, % |

| 0.05-0.15 | 0.30-0.60 | 0.025 ubuninzi | 0.025 ubuninzi | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 |

Iipropati zoomatshini

| Amandla Okuqina, MPa | Amandla eSivuno, iMPa | Elongation, % |

| 415 imiz | 205 imiz | 30 imiz |

Ngaphandle kweDiameter kunye noNyamezelo

|

ASTM A450

| Ishushu esongwayo | Ububanzi bangaphandle, mm | Ukunyamezela, mm |

| OD≤101.6 | +0.4/-0.8 | ||

| 101.6<OD≤190.5 | +0.4/-1.2 | ||

| 190.5<OD≤228.6 | +0.4/-1.6 | ||

| I-ASTM A530 kunye ne-ASTM A335 | NPS | Ngaphandle Ububanzi, intshi | Ukunyamezela, mm |

| 1/8≤OD≤1-1/2 | ±0.40 | ||

| 1-1/2<OD≤4 | ±0.79 | ||

| 4<OD≤8 | +1.59/-0.79 | ||

| 8<OD≤12 | +2.38/-0.79 | ||

| OD>12 | ±1% |

Ubunzima bodonga & Ukunyamezela

| ASTM A450 | Ishushu esongwayo | Ububanzi bangaphandle, mm | Ukunyamezela, % |

| OD≤101.6, WT≤2.4 | +40/-0 | ||

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD≤101.6, WT>4.6 | +28/-0 | ||

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD>101.6, WT>4.6 | +28/-0 | ||

| I-ASTM A530 | NPS | Ngaphandle Ububanzi, intshi | Ukunyamezela, % |

| 1/8≤OD≤2-1/2 | +20.0/-12.5 | ||

| 3≤OD≤18, WT/OD≤5% | +22.5/-12.5 | ||

| 3≤OD≤18, WT/OD>5% | +15.0/-12.5 | ||

| OD≥20, WT/OD≤5% | +22.5/-12.5 | ||

| OD≥20, WT/OD>5% | +15.0/-12.5 |

Umgangatho

I-ASTM A335-yeMbhobho yeSteel engenamthungo yeFerritic alloy-Steel yeNkonzo yoBubushushu obuphezulu

I-ASTM i-A519-yeKhabhoni engenamthungo kunye ne-Alloy Steel Mechanical Tubing

I-ASTM A213–yeBhoyila ye-Ferritic engenamthungo kunye ne-Austenitic Alloy-Steel, isifudumezisi esiPhezulu, kunye neeTubhu zokuTshintshisana ngobushushu

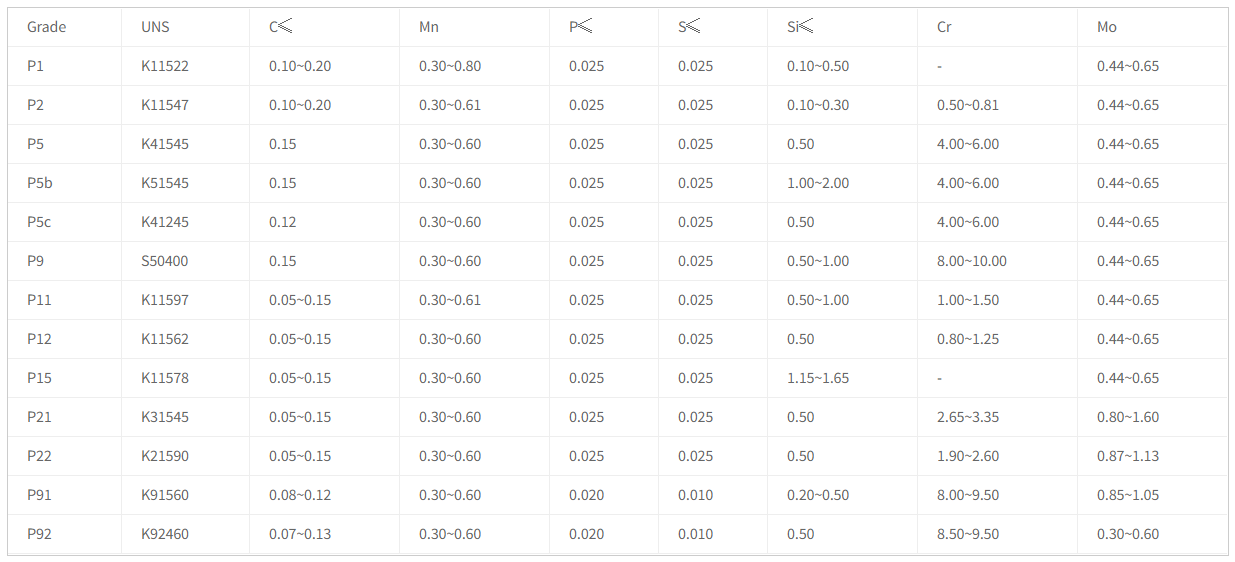

I-ASTM ASME (S)A-335/(S)A-335M iBanga kunye noBume beMichiza

Qaphela: (S)A335 P91 ezinye iikhemikhali ezidityanisiweyo zezi: V 0.18~0.25;N 0.030~0,070;Ni ≤ 0.40;Al ≤ 0.04 ;Nb 0.06~0.10

(S)A335 P92 olunye ukwakheka kweekhemikhali zezi: V 0.15~0.25;N 0.030~0,070;Ni ≤ 0.40;Al ≤ 0.04 ;Nb 0.04~0.09;W 1.5~2.00 ;B 0.001~0.006

Ukupeyinta&Ukwaleka

Ukupakisha okumnyama, i-oyile / ivanishi, i-FBE, i-2PE, i-3PE, i-galvanized njl Iinkcukacha zokupakisha: Ukupakisha kwiingxowa okanye kwiimfuno zomthengi

Ukupakisha&Ilayisha